Our precision engineering services

CNC MILLING

Our CNC milling sections make use of the latest multi axis machines. These range up to 1300 x 550 x550 mm in capacity and offer the very latest in machine technology.

Programming is conducted off-line by highly skilled and experienced engineers using the most current CADCAM software packages, thus enabling us to work from CAD files as well as hard copy drawings.

Whether it be a one off prototype or a large batch quantity, we are well positioned to provide the highest quality and complex 3 dimensional / surface machining.

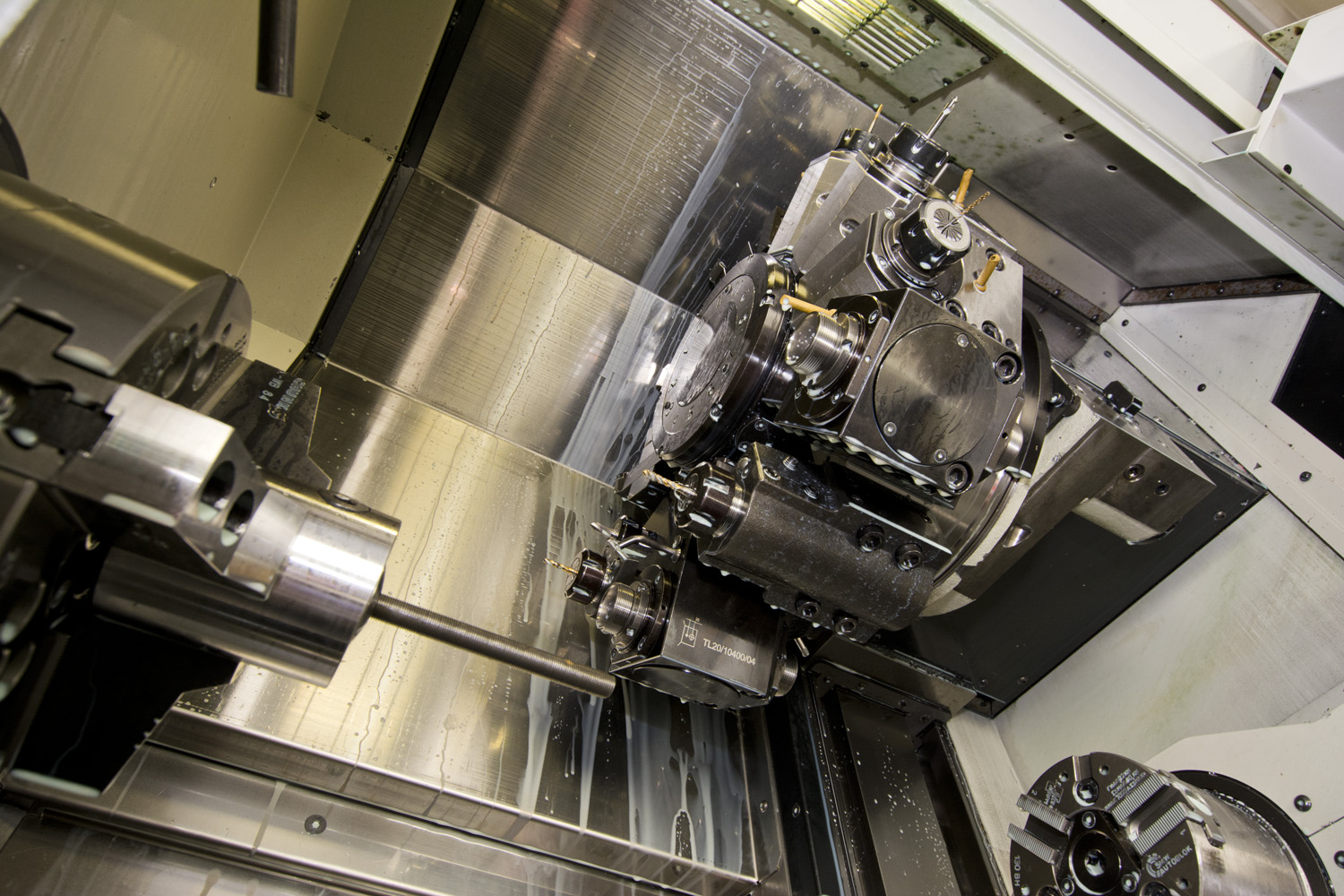

CNC TURNING

We have a mixture of fixed-head and sliding-head lathe technology, enabling us to meet a wide variety of customer part requirements. We are known in the industry for our ability to produce complex parts for a number of sectors. It is the combination of the range of our machinery and knowledge which enables us to do this.

In addition to a pure turning centre, all of our lathes have live tooling capability in c and y axis; this means that we can machine milled features directly onto the turned component, eliminating the need to transfer to a separate milling machine. This can significantly reduce part costs for our customers.

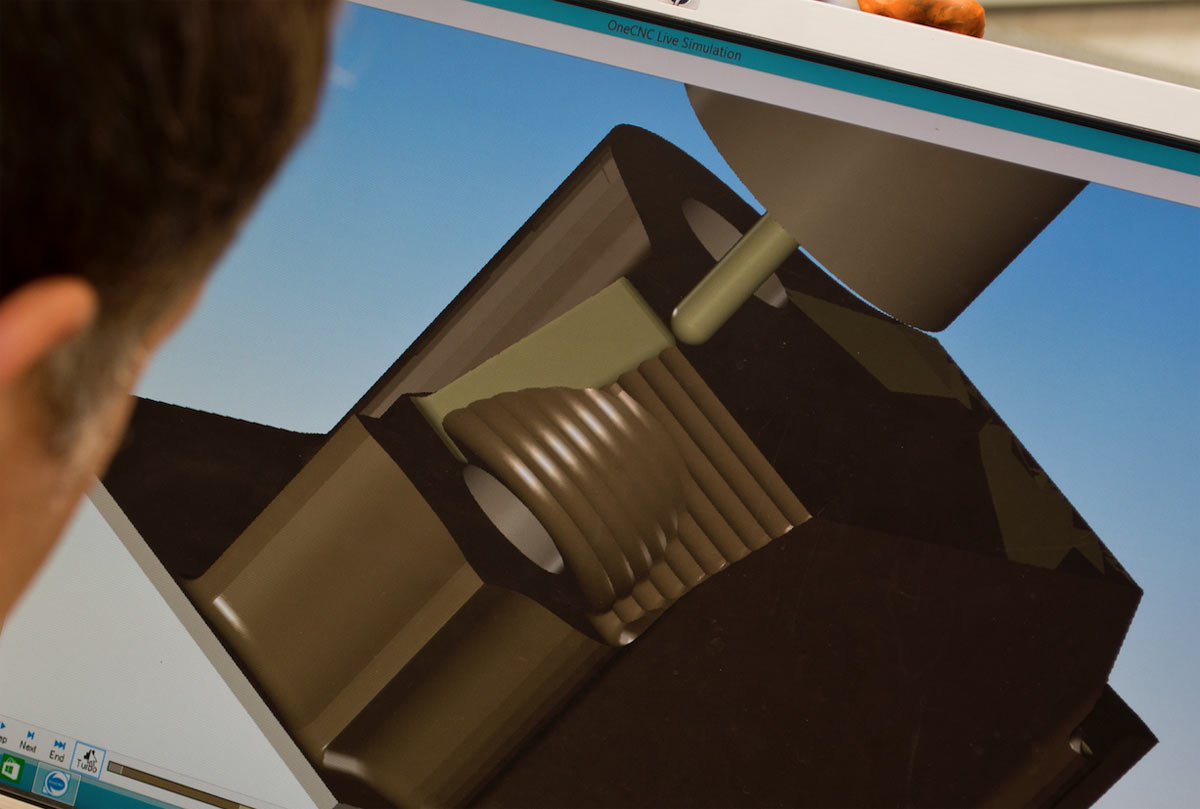

CAD CAM SERVICES

Design and prototyping through to production.

We operate fully integrated design and manufacturing software in order to maximise the performance and capabilities of our multi axis machines tools.

Using OneCnc Cad/Cam software we can accept various files including IGES, DXF and STEP thus giving the company the capability to offer parts on a quick turnaround from design to delivery.

We continually update the software enabling us to remain as efficient as possible and in the knowledge that we are producing parts in the most economical manner.

We also ensure that our engineers have the required training and experience to use this technology.

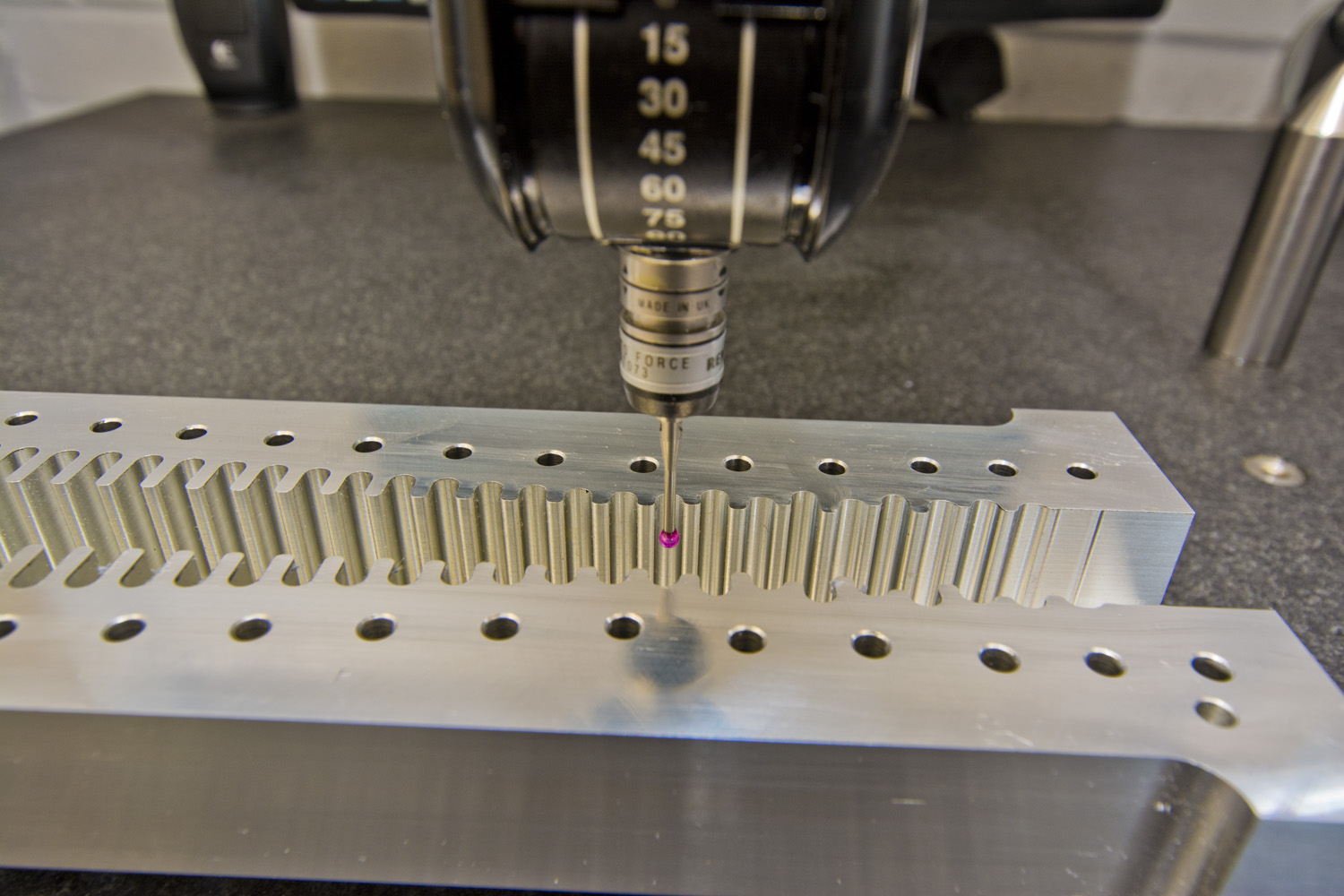

QUALITY CONTROL

- Automatic measurement routines

- Automatic feature recognition

- 2D and 3D inspection

- Geometric feature inspection

- Free form curve inspection

- DXF data import/export

We have a dedicated inspection department with a full range of measuring equipment.

All manufactured components undergo a full inspection before despatch from our works.

We undertake a comprehensive quality control process in all work undertaken for our clients from initial consultation through to the final product.

Contact Us

Contact us today using the details on our contact page.

We are always happy to give you an estimate or answer any queries you may have.